As solar deployment surges across the United States, the conversation is shifting from how fast we can build to how well we can sustain. In 2024 alone, nearly 50 gigawatts (GWdc) were installed and came online, representing nearly two-thirds of all new electricity-generating capacity. But as new systems are energized, a growing portion of the fleet is aging, and with that comes a new set of challenges.

Over the next five years, approximately 23 gigawatts of U.S. solar capacity will reach the 15-year mark. As these assets age, owners face increasing financial risk with extended deterioration, increased equipment failure rates, and obsolete equipment. While durable, solar panels naturally decline (typically 0.5% to 0.8% per year), but many other factors affect asset performance, including component failure. For example, thermal stress, equipment wear and useful life all affect subcomponents of solar Photovoltaic systems, affecting critical elements like electrical connections, cooling systems and inverter controllers.

To use an analogy, the inverter is like the car’s gearbox; without it, the vehicle won’t move. As solar module technology has become more efficient, so have the inverters. While efficiency and product improvement are beneficial for the industry, this creates product availability and resource gaps for legacy assets. Unsurprisingly, the immediate threat to the long-term performance of solar assets is inverters.

This combination of revenue loss from degradation and the acute risk of sudden equipment failure puts escalating pressure on an asset’s lifetime performance and profitability. To safeguard long-term value, the industry must evolve beyond traditional maintenance and adopt smarter, data-driven strategies.

Predictive O&M: A Smarter Approach to Solar Performance

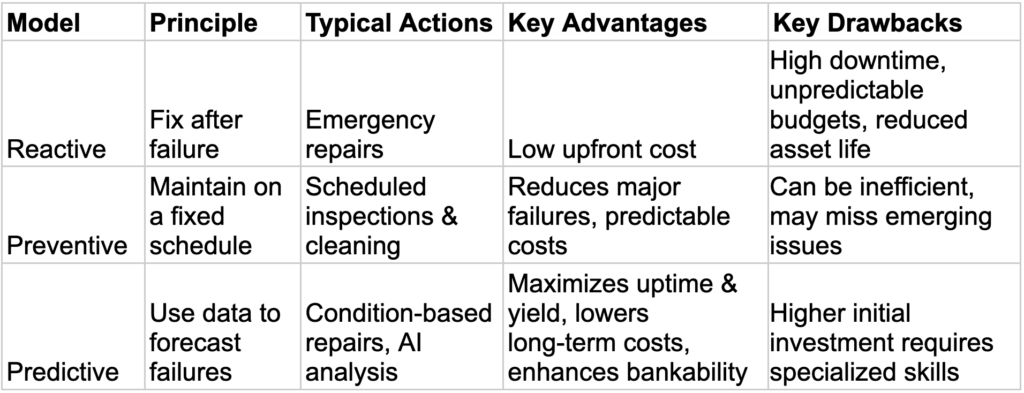

Smart Operations & Maintenance (O&M) is redefining how we manage solar assets. Unlike reactive or time-based preventive maintenance, predictive O&M can use real-time data to anticipate issues before they escalate. This shift transforms O&M from a cost center into a strategic asset planning team.

Leveraging real-time information from smart technologies, such as drones, sensors and AI, allows for condition-based interventions rather than costly, reactive repairs. This approach not only reduces unplanned outages by targeting the root cause of the issues but also improves productivity and lowers maintenance costs.

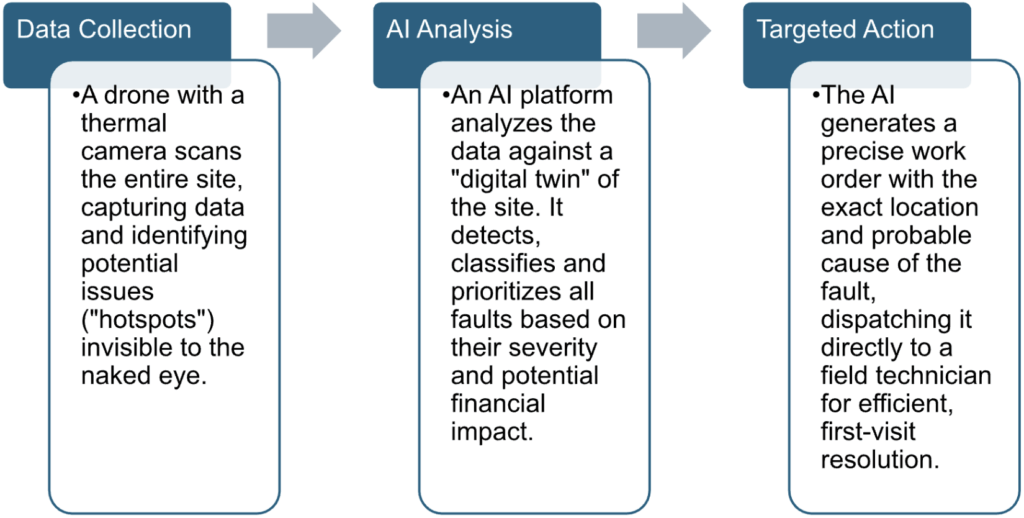

Technology in Action: A Day in the Life of a Smart Solar Site

But what does this predictive, data-driven strategy look like in practice? It’s the deployment of data systems from drones equipped with thermal cameras. Comprehensive data matrices are built out for each asset and asset type, typically referred to as “digital twins”. And AI systems that leverage the data sets, photos and systems to create actionable repairs or additional maintenance inspections. This technology turns raw data into insights, enabling teams to act quickly and efficiently before problems impact performance.

The Power of a Portfolio-Wide View

While site-level technology provides detailed insights, managing a national portfolio requires a broader perspective. Standard Solar’s Remote Operations Control (ROC) center aggregates data from all facilities: SCADA systems, aerial inspections, technician reports and weather feeds to generate a comprehensive picture of asset performance.

This centralized system allows our dedicated team of experts to analyze performance and operations and maintenance needs across the fleet. Underperformance and safety issues identified could be site-based or regional. For example, underperformance due to a lack of vegetation maintenance, defective devices based on trends of similar failures, or general installation practices that require portfolio-wide investigation. Partnering with Standard Solar provides the benefit from the collective knowledge and experience of managing a diverse, nationwide asset portfolio.

The Bottom Line: Protecting Project Bankability and Maximizing ROI

Ultimately, predictive O&M is a strategic function centered on risk mitigation and value preservation. It directly protects an asset’s financial health by ensuring production forecasts are met, minimizing unplanned downtime and extending equipment life to defer costly capital expenditures. An effective, comprehensive maintenance strategy supplemented by predictive maintenance activities maximizes energy output while lowering operational costs. This benefit directly reduces a project’s Levelized Cost of Energy (LCOE), the ultimate measure of economic competitiveness against other energy sources.

Operational excellence creates significant competitive advantages by strengthening a project’s position. When securing financing, a well-performing portfolio reinforces the industry’s credibility and support necessary for sustained market momentum.

Partnering for the Future of Solar Performance

As the solar industry matures, success will be measured not just by capacity installed, but by energy delivered over time. This shift requires a new mindset — one that views solar assets as long-term infrastructure requiring intelligent, proactive care.

Choosing a partner who shares this commitment to performance is the key to delivering long-term success. Fill out a form to discuss how our advanced O&M services can optimize your solar portfolio.

More Recent Blog Posts

The Budget Barrier: A New Financial Path for School Solar

February 24, 2026

Standard Solar · 3 min read

Massachusetts: A Visionary State in Community Solar Growth

February 13, 2026

Standard Solar · 3 min read

Unlocking Student Imagination with Solar Energy

January 20, 2026

Standard Solar · 4 min read

Delivering on Our Promise: 2025 in Review

December 11, 2025

Scott Wiater · 3 min read

Share